Udo's Resin Printing Troubleshooting Guide

Udo's Resin Printing Troubleshooting Guide

General infos

This is a living document, with the goal to support you with every problem you could have during resin printing. There is already a really good guide for FDM printing, if you have issues here, check this guide: A visual Ultimaker troubleshooting guide. If you have any problems that are not listed here, feel free to contact us, so we can add your problem here and help you. If you think that something is wrong here, needs a better explaination, better photos or additional solutions, ..., please also contact us, so we can improve: info@udos3dworld.com

If you want to support us and our work, check our patreon: patreon.com/Udos3DWorld

Plateaus / Delamination / "Pancaking"

Newly hardened resin is bound too weak to the main object, so its connection rips off and the part stays on the FEP. At some point, other parts of the print might connect to this thing and then it can detach again from the FEP, having a flat shape that appears somewhere in the print. Check if above the failed part the ends of supports are showing. If only the supports are showing, this suggests a support failure, so the solution would be to increase the amount and strength of the supports. If there is a flat part of the model, this suggests underexposure or old FEP. Increasing the exposure time or switching the FEP will help here.

Parts of the model shifted upwards

This most likely happens due to failing supports, after printing a part of the model, the supports fail (and this part stays on the FEP) and after some time, other parts of the model bond with this failed object and fuse it back to the main model. Often has a flat surface on one side, comparable to plateaus. Strengthen your supports!

Support failure

Comparable to the problem above, but the part does not re-attach to the model but stays on the FEP until you peel it off. You can usually see all the top parts of your support structure but no object connected to them, and some flat objects still sitting on your FEP. Again, strengthening your supports work, but other solutions for underexposure might help here, too, since they strengthen everything. You can also change the orientation of your parts to minimize the cross-section, so the forces pulling on the supports are reduced.

General Failure at one height

It's quite hard to figure out the real problem here, could be that the printer just did something wrong. If it occurs only once and at a random height, a simple retry might solve the problem. It could also be a weak layer bonding. If this happens multiple times at the same height or appears at heights where the model changes much, (which might lead to a reduced light output due to a slight decrease in supply voltage), or even across multiple parts (as in the image above), this is usually an underexposure problem. An old FEP can also be the reason for this problem as it effectively decreases the amount of light that can pass through. Another reason for this could be that the print file saved to the stick / SD card has some problem (e.g. you pulled out the stick of your computer too fast) or the stick is full. Try to re-slice it and make sure the file was saved successfully. Yet another problem could be a small particle falling on the screen at effectively causing a distance between the printed model and the screen, so nothing sticks together anymore.

Cracked Surface

This usually happens if the object stays too long in the washing alcohol. Try to reduce the time inside here.

Resin liquidification

This can happen if liquid resin is trapped inside the object and attacks the solid outer hull later or the resin itself is not fully UV-cured. Sometimes, holes appear in the model, sometimes only the outer surface becomes shiny at some spots. If you print a hollow object, make sure that there are holes to wash it also from the inside and make sure to wash it properly to get all the resin out. Make sure to cure all models long enough, and if these symptoms show, cure them another time.

Bad leveled buildplate

Your parts are not sticking to the buildplate or only on one side? This might be due to a badly leveled buildplate or an unsufficient burn-in time, so you could also try to increase the layer time for the first layers.

Underexposure

Underexposure means that the print is not cured sufficiently, so the layer bonding (or support-model bonding) is weak and can fail. This usually shows in plateaus or supports failing. Solution: Increase the exposure time. Another reason for underexposure might be temperature issues. Most resins are quite sensitive for temperature changes, if it gets too cold, some really refuse to print properly. Try to keep your environment temperature stable, or try to adapt the exposure time accordingly, if the temperature changed.

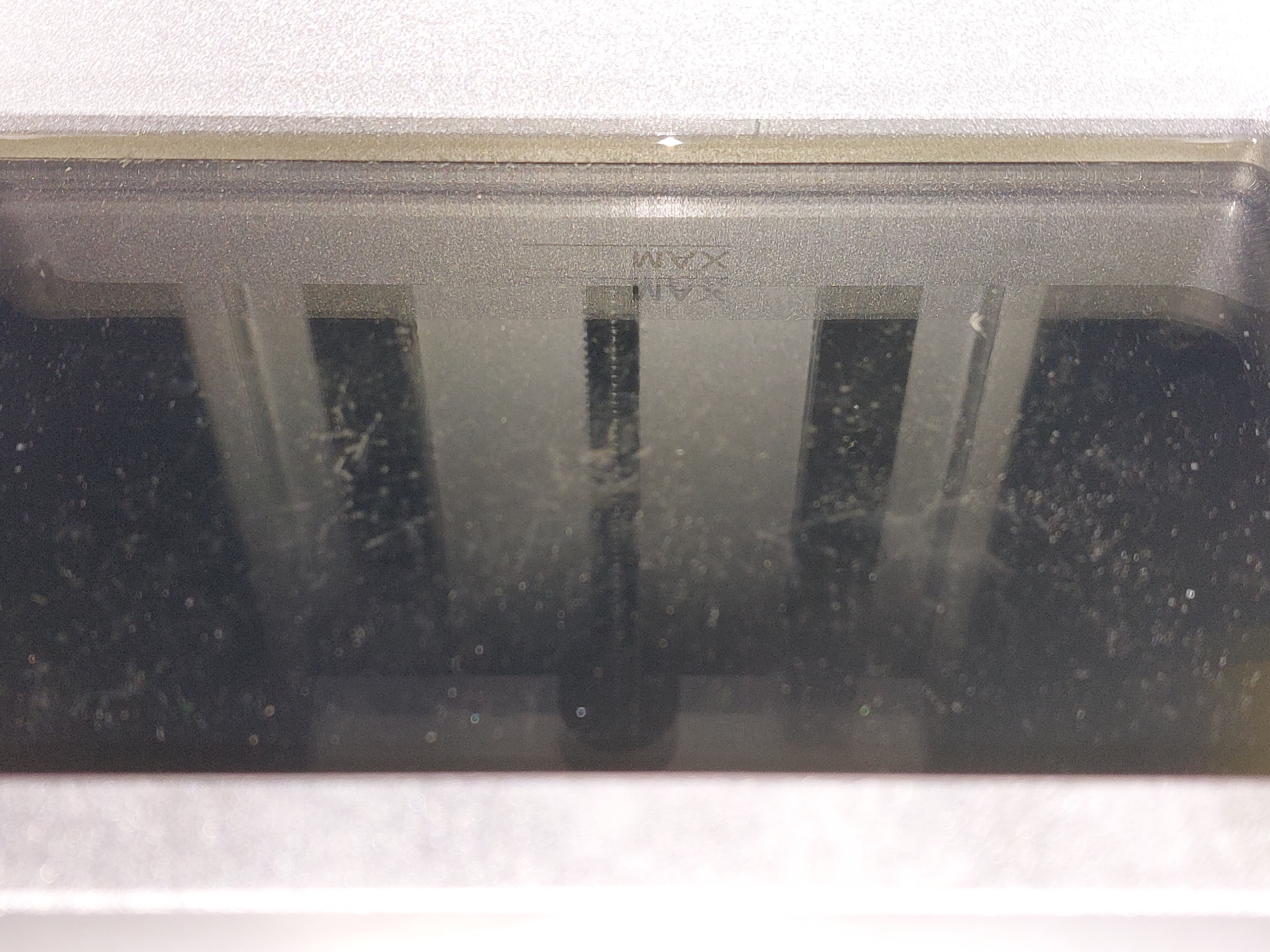

Old FEP

It's really hard to get a good photo of this... After a while, an FEP screen loses parts of its transparency and becomes milky-greyish, especially at positions where most models are placed. Placing the models at other locations might be an easy and fast solution, but eventually, the FEP has to be changed.